Mousegunner's GLOCK Pistol Page

I am a fan of GLOCK pistols, and have decided to try to build a page here that will add to the internet store of GLOCK knowledge. I do not claim to be a GLOCK expert, but I have owned GLOCK models 27, 29 and 22; and am somewhat familar with GLOCKS. (Click HERE for my GLOCK 27 Review.) (Click HERE for photos of my G22.) I hope you find this page useful and entertaining. I am sure you will find a few things here that you won't find anywhere else. Follow the links at the bottom of the page for more GLOCK information. Note: I have borrowed photos from around the internet, as well as using my own photos. If I have used one of your photos, and you want credit, or you want the photo removed, Gaston GLOCK, born in 1929, is highly regarded as a genius of the firearm industry. (He has been ranked with Browning, Kalashnikov and Stoner.) His GLOCK "safe-action" pistol is known to be one of the better auto loading pistols in existence. Many think it is the best ever designed. The GLOCK line of pistols has often been copied by other companies. For example the Smith and Wesson SW9VE (Sigma). In the two photos below, you can see how S&W copied the GLOCK concept of the polymer frame. It has been said that the Sigma was such a close copy that some of the internal parts could be exchanged for GLOCK parts, and it would still function.

just email me and let me know.

GLOCK sued Smith & Wesson in early 1994. claiming "tortious acts, including without limitations, patent infringement, federal unfair competition, common unfair competition and deceptive trade practices." All this because Smith and Wesson had developed their own polymer pistol (called a "Sigma," which was extremely similar to the GLOCK. Smith and Wesson replied, "We firmly believe the suit to be totally without merit and will act accordingly."

GLOCK then sent an ultimatum to its dealers, giving them 15 days to decide on which to carry, the GLOCK or the Sigma. "If your decision is to continue to distribute Smith & Wesson products, your contractual relationship with GLOCK Inc. will be terminated," GLOCK'S letter read!

Finally, Smith and Wesson agreed to "remove the surface located below the sear in the Sigma Series Pistols, which GLOCK contends is a positive guide means, and GLOCK has agreed that such a modification would resolve the patent infringement claim."

The settlement is thought to have cost Smith and Wesson between five and eight million dollars. Smith and Wesson continued to work on their Sigma pistol. It is now in a "third generation" configuration, and is thought by most people to be a very decent firearm, but with a difficult trigger pull. It is available in both 9mm and 40S&W varieties, and is less expensive than a GLOCK.

It would be accurate to say that the multitude of polymer pistols available in today's market (S&W, XD, FNH, Steyr, Kel-Tec, Ruger, etc.) owe their inspiration to GLOCK, and there are many similarites between them and the GLOCK pistols. The GLOCKS however continue to have the best reputation for reliability and durability. The GLOCK pistol still defines the mark of excellence that all the others shoot for.

Activate this mp3 player for an important message...

GLOCK headquarters are in Deutsch-Wagram, a small town in Austria, a suburb of Vienna, in the federal state of Lower Austria. It lies 15 km northeast of Vienna and has a population of 6,808 as of the 2001 census. Deutsch-Wagram was the location of the Battle of Wagram fought during the Napoleonic Wars from July 5-6 1809. Here is a map of Austria showing the location of Vienna (Wien), and another map of Vienna, with Deutsch-Wagram marked for identification.

Here is a photo of the City Hall ("Rathaus" in German) in Deutsch-Wagram.

German is of course the language of Austria, but Austria is a sovereign nation, not part of Germany.

In 1963 Gaston GLOCK (born in 1929) created GLOCK GmbH in Deutsch-Wagram, Austria.

In Germany, there are two types of companies: publicly traded and privately held. The acronym 'GmbH', which is written after the name of the company, designates a company as private in Germany. The letters stand for Gesellschaft mit beschränkter Haftung which means a "company with limited liability." GmbH companies are incorporated and are legal entities unto themselves. These companies must have a minimum of two partners and may be, but do not have to be, owned by a public company. German companies that are publicly traded are designated as such by the letters "AG" after the company name. "AG" is an abbreviation for the German word Aktiengesellschaft, which translates to "corporation"' in English.

GLOCK began manufacturing miscellaneous products including doorknobs and hinges; and became a well-respected company in the fields of metallurgy and polymers. He then began making sundry items for the Austrian military, for example: knives, entrenching tools, hand grenades and machine gun belts. Herr GLOCK writes that he invented his famous GLOCK pistol in 1980 (see below).

In May 1980 the Austrian army began searching for a new 9mm pistol to issue it's troops. The Austrian government invited the GLOCK company to bid on a contract to replace the entire inventory of obsolete pistols (Walther P38) then in use by the Austrian military.

Austria insisted that every gun submitted for consideration had to meet or exceed SEVENTEEN qualifications:

- Must be semi-automatic

- Must fire the 9mm parabellum round

- Muzzel energy must meet a designated standard

- Magazine must be loaded without use of tools

- Magazine must hold at least eight rounds

- Must be able to be used with only one hand

- Must continue to function after being dropped onto a steel plate from a height of two meters

- Must be easy to dismantle without tools

- Maintainance and cleaning must be possible without tools

- Gages and other measuring devices must not be necessary for long-term maintainance

- Total number of parts must be 58 or less

- Manufacturer must supply complete blueprints along with the test pistol

- All component parts must be interchangeable with other pistols of the same design without adjustments

- No more than 20 mal-functions will be permitted in the first 10,000 rounds fired

- After 15,000 rounds all parts must be secure and intact, even under stress of a "proof round" at 15,001

- Case ejection must not endanger the shooter

- If no submitted pistol achieves more than a score of 70%, then no pistol at all will be accepted

|

Gaston GLOCK conferred with European firearms experts, who assisted him in designing a new pistol. The prototype GLOCK Model 17 pistol was quickly developed and submitted to the Austrian military for testing. The GLOCK design met or exceeded all of the Austrian Armed Forces requirements. In late 1982, the Austrian government chose the GLOCK 17 over all other pistols, and the Austrian army placed an initial order for 25,000 new GLOCKS. The first Austrian Army GLOCK was known as the P80 (Pistole 80). GLOCKS are extremely durable and reliable. CLICK HERE to view the famous internet GLOCK "torture test." During the Cold War in the early 1980s, other NATO nations began placing the GLOCK pistol into service, beginning with the Netherlands and Norway. It is likely that this use within NATO made many observers around the wold notice and become interested in GLOCK pistols. Starting with Sweden, non-aligned nations began using GLOCKS. After the break-up of the Soviet Union, nations which at the time were using Makarov pistols began abandoning them in favor of GLOCK pistols, for example Latvia and Lithuania. Special Op forces in the UK, Italy, Slovenia, Greece, Iceland, Finland and Belgium, along with other nations, all have turned to GLOCK. |

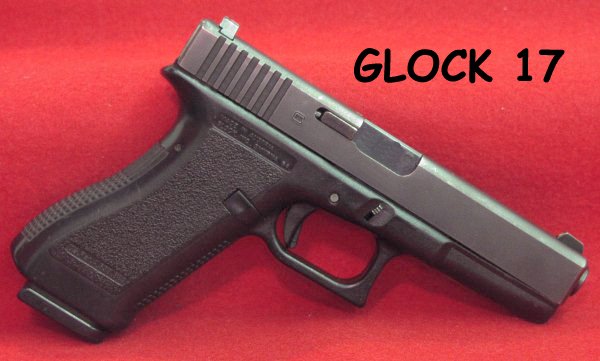

Here is a photo of a "First Generation" GLOCK 17, very similar to the original GLOCK that started the GLOCK pistol avalanche.

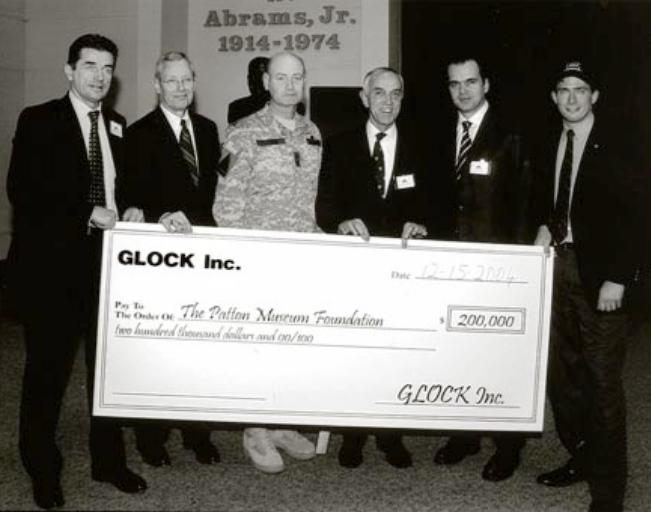

In the 2009 "Annual Message from the Founder," Gaston GLOCK wrote: "I am gratified that our GLOCK product line continues to expand. Since 1980 when I made the first GLOCK pistol, the GLOCK 17, produced for the Austrian Army, I have enjoyed great personal pride in seeing the GLOCK pistol line grow to meet diverse mission requirements and individual preferences...As in years past, our success in sales and growth have not blinded us to the needs of others. In recent years, GLOCK, Inc. philanthropic gifts have topped a total of $1 million, and these will continue. This past year the Special Operations Warrior Foundation, Young Marines and Concerns of Police Survivors were major beneficiaries of GLOCK, Inc.'s program of giving back to the communities it serves."

This group photo was made in 2004, showing GLOCK's gift of $200,000 to the Patton Museum Foundation.

The first GLOCK pistol was his seventeenth patent, and he labeled it the GLOCK 17.

It was in 9mm and had a frame made with a new light weight polymer with embedded

metal inserts to assist in wear reduction and accuracy. Many people have come to believe that the GLOCK pistol is the perfect handgun, which led to the company motto, "GLOCK Perfection".

|

In 1985, after evaluating the U.S. market for the GLOCK pistol, GLOCK began taking steps to bring the GLOCK pistol to the United States. In July, GLOCK submitted a model 17 to the Bureau of Alcohol, Tobacco, and Firearms for import evaluation. The BATF required two changes be made to the GLOCK pistol before they would allow it to be imported. These changes included the addition of a metal serial number plate and replacement of the fixed rear site with an adjustable one.

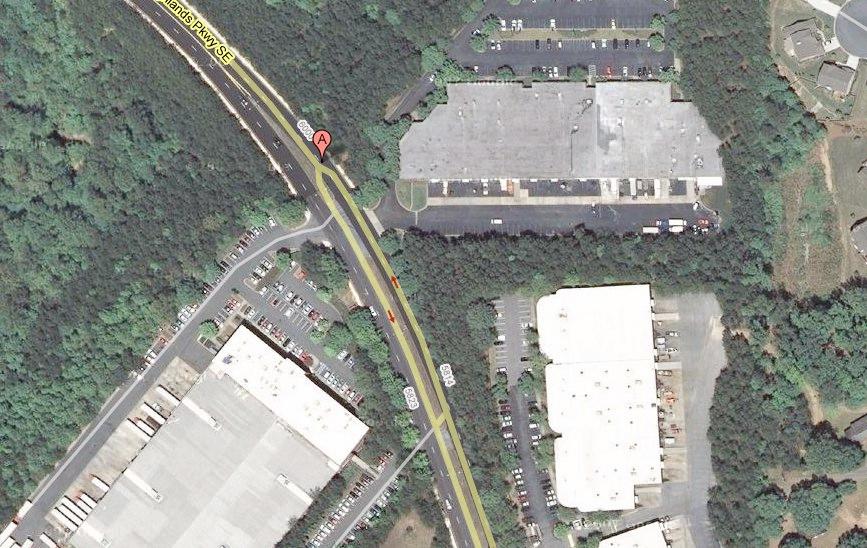

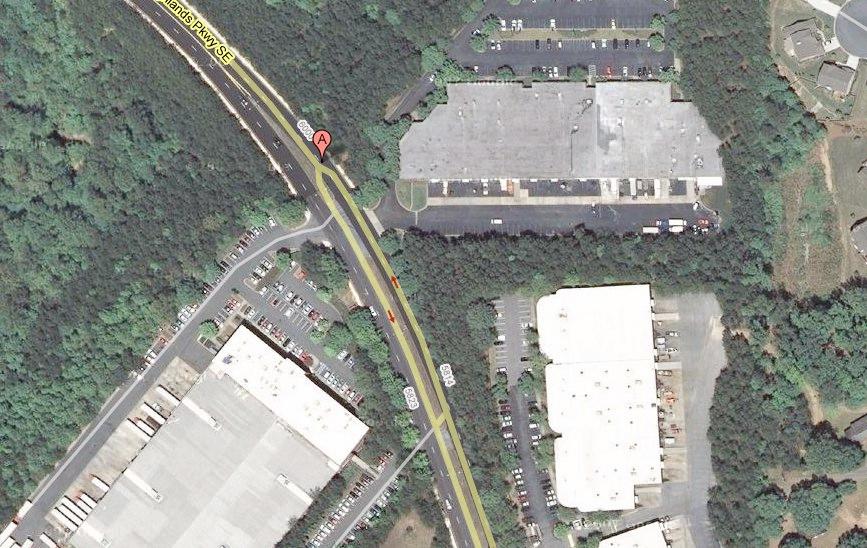

Later in 1985, GLOCK, Inc. was formed in Smyrna, Georgia, as the importer and distributor of GLOCK pistols in the U.S. Final approval for importation of the GLOCK pistol came from the BATF in January 1986. An additional plant was constructed at the Smyrna, Georgia home of GLOCK, Inc. in 1990. Although all GLOCK pistols are still manufactured in Austria, the new GLOCK facility at Smyrna now assembles and test fires all pistols imported to the United States. (The photo to the left is the Smyrna City Center.) |

Some photos of the GLOCK facilities in Smyrna...

The building on the lower right in the birdseye view is the GLOCK Training Center.

Here are four photos of the Smyrna GLOCK facilities from the street in front of their buildings.

These excellent photos were contributed by Jon Merrow (Jonm61 on GLOCKTALK.) Thank you Jon!

GLOCK handguns are in use by a majority of US and international law enforcement agencies and military personnel. The St. Paul Minnesota Police Department was the first American police department to adopt GLOCK firearms (October 1987.) By 1992, some 350,000 pistols had been sold in more than 45 countries, including 250,000 in the United States.

GLOCK handguns are also very popular with civilians, especially for personal protection and target shooting. GLOCK currently produces 40 models of handguns. The US-led Multi National Force-Iraq has equipped and trained the Iraqi military and the Iraqi National Police with tens of thousands of GLOCK sidearms purchased by the Iraqi government, and/or donated by friendly nations.

GLOCK offers a discounted price, and a free extra magazine, to law enforcement officers in the United States.

Scanned from 2009 GLOCK Autopistols

Each GLOCK (of whatever caliber) is a short-recoil-operated locked breech pistol that uses a modified Browning cam-lock system adapted from the early 20th century Browning Hi-Power pistol. The firearm’s locking mechanism utilizes a linkless, vertically tilting barrel with a rectangular breech that locks into the ejection port cut-out in the slide.

Photo of a Browning Hi-Power 9mm Pistol...

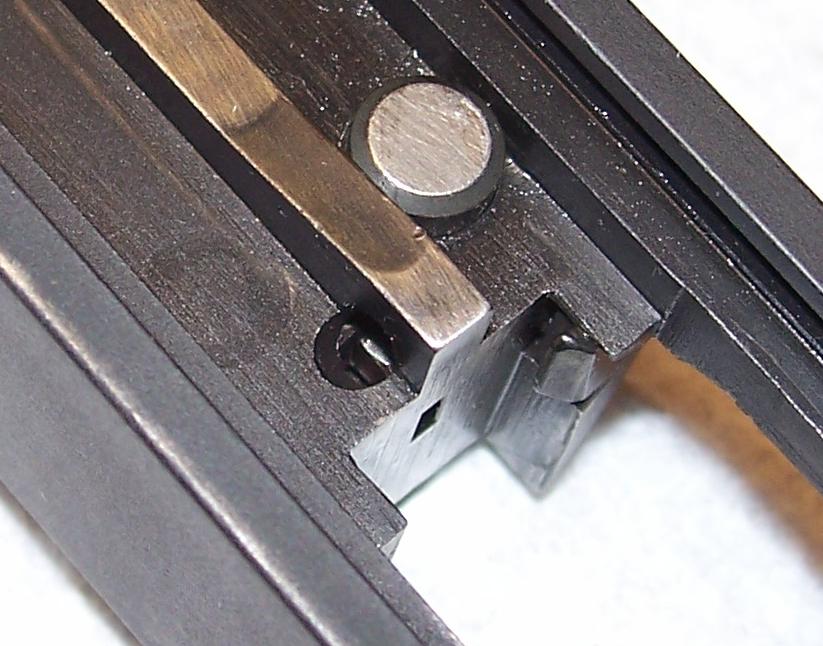

During the recoil stroke, the barrel moves rearward initially locked together with the slide approximately 3 mm (0.12 in) until the bullet leaves the barrel and chamber pressure drops to a safe level. A ramped lug extension at the base of the chamber then interacts with a tapered locking block in the frame, forcing the chamber downward and unlocking it from the slide. This locking block halts the barrel's rearward movement, while the slide continues back under recoil. The claw of the extractor (set in the side of the slide) pulls the spent cartridge from the chamber. Then the extracted shell hits the finger-like ejector, which throws it out of the gun.

Animated Cartoon of the GLOCK Action: CLICK HERE.

(Click on the various little "check boxes" to make the parts of the GLOCK transparent.)

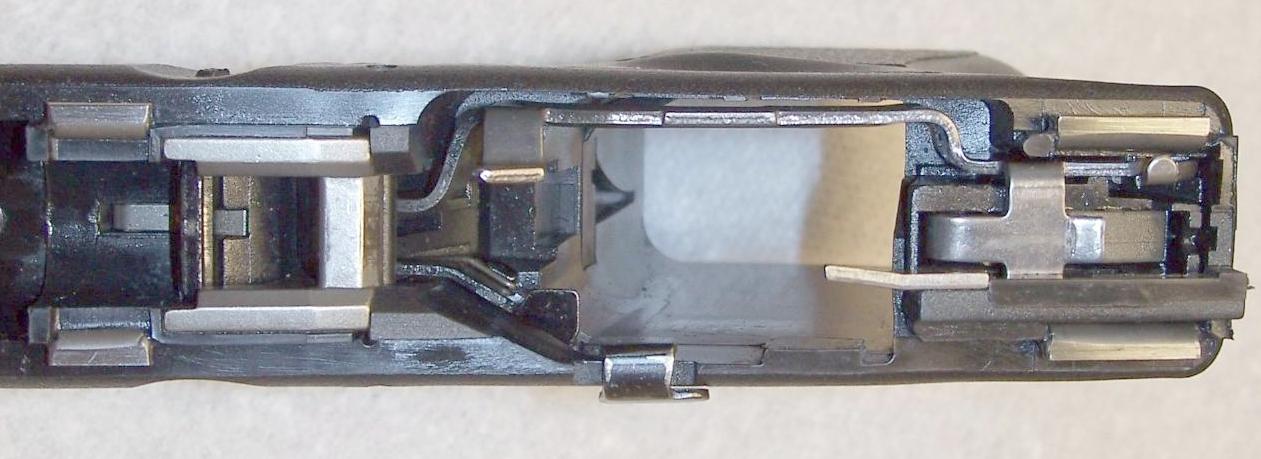

The striker firing mechanism has a spring-loaded firing pin that is cocked in two stages, powered by the firing pin spring. When the weapon is first charged by pulling back on the slide and chambering a round, the firing pin is in the half-cock position. Pulling the trigger fully cocks the striker. At the end of the trigger pull, the trigger bar is tilted downward by the disconnector, which releases the spring-powered firing pin to strike and fire the cartridge. The disconnector also resets the trigger bar so that the striker will be captured in half-cock at the end of the firing cycle. This is referred to as the "Safe Action" trigger by GLOCK. The disconnector also prevents the pistol from going full-auto.

Each GLOCK pistol has three independent safety mechanisms: an external trigger safety and two automatic internal safeties - a firing pin safety and a drop safety. The trigger safety is a small inner lever contained in the trigger. Pressing the lever with your trigger finger, as you shoot the gun, activates the trigger bar and sheet metal connector. One of the internal safeties is a solid hardened steel pin which blocks the firing pin channel (preventing forward movement of the firing pin). The firing pin safety is only pushed upward to release the firing pin for firing when the trigger is actuated and the safety is pushed up through the backward movement of the trigger bar. There is also a drop safety that is only released when a shot is triggered by pulling the trigger.

The safeties disengage in sequence when the trigger is squeezed, and then re-activate when the trigger is released. This guarantees safe handling of the pistol, even with a cartridge in the chamber. However, in the case of a defective non-firing round, there is no way to re-cock the striker without pulling back on the slide and ejecting the non-functioning round.

Most GLOCK pistols feed from a double-column box magazine. Magazine construction features a steel body overmolded with plastic. A plastic "follower" at the top of a steel spring pushes the rounds up into the gun. After the last round has been fired, the slide remains open on the slide stop. Here are four photos of some .40 caliber GLOCK magazines from different perspectives. Note the follower is a "5" rather than "8." (These are older magazines.)

The slide stop release lever is located on the left side of the frame directly beneath the slide and can be released by the thumb of the shooting hand.

The cold hammer-forged barrel has a hexagonal (six sided) interior bore with a right-hand twist.

This type of "rifling" provides a better gas seal around the projectile than ordinary true rifling. However, non-jacketed lead bullets should not be shot from such a barrel. The barrel may take on excessive amounts of lead, which leads to higher than normal pressures, and has been known to cause barrels to explode. Always shoot copper jacketed bullets from a GLOCK.

How is a GLOCK barrel manufactured?

GLOCK barrels are formed by "cold hammer forging." First, a bar of steel is drilled through, lengthwise of course. The resulting infant "bore" is reamed out to a precise size, and polished. Next, the outside of what will become a barrel is turned to a precise dimension and degree of smoothness. Then the barrel/chamber in process goes into a barrel forge machine. A "mandrel" which is the exact shape of the finished bore is inserted into the not yet perfect bore, and the barrel is hammered without mercy until the bore and chamber exactly match the mandrel. The mandrel is removed from the forged barrel/chamber, which is then machined to the exact size needed for the caliber barrel being produced. Finally it is marked with a serial number, and given the Tenifer treatment. (More about Tenifer below...) The bore has a mirror-like polish, but the exterior of the barrel is merely smooth enough to insure good functioning with the slide. Some barrels appear rougher than others. For example, in the photo below, the G26 (9mm) barrel appears rougher than the G27 (40S&W) barrel.

The GLOCK's frame is molded from a nylon-based polymer. (CLICK HERE FOR EXCELLENT FRAME INFORMATION.) The frame holds four small hardened steel guide rails for the slide: two at the rear of the frame, and the remaining pair above and in front of the trigger guard. The frame also holds the locking block, which is an investment casting that engages a 45° camming surface on the barrel's lower camming lug beneath the chamber. It is retained in the frame by a steel axis pin that also holds the trigger and slide catch. The trigger housing is held to the frame by means of a plastic pin.

The Lug On the Bottom of the Chamber

The chunky slide is carved from a block of ordnance-grade steel using CNC machinery. The barrel and slide are finished with a nitriding process called "Tenifer."

Surface hardening of steel and iron can be done by either allowing the surface of metals to react with certain minerals. "Tenifer" is a term a chemical bath nitriding process whereby nitrogen is chemically released and introduced into the surface of the steel at a high temperature to allow the chemical process to take place.

Using liquid bath techniques, the temperature required to activate the reaction is about 575 degrees Celsius. The bath is in a molten, nitrogen-bearing liquid, usually containing cyanides or cyanates. Cyanide-free liquid has also been used in some modern techniques. When using cyanide-free liquid, Tenifer is actually a salt bath nitro-carburing technique because it starts (first reaction) with Carbon-Nitride (CN) and allows it to react with Oxygen (0)to produce Nitro-carbon-dioxide by-product plus Nitrogen. The simultaneous second reaction takes place when nitrogen (N) is in contact with Iron (Fe) to form FeN (iron-nidride). The Tenifer coating "composition" of GLOCK's steel slide is essentially that of FeN.

Three hardening processes are applied to the slide and barrel prior to the final nitride bath. The Tenifer finish is approximately 0.5 mm (0.02 in) in thickness.

The Tenifer FeN coating increases the surface wear resistance. The corrosion resistance is also better for iron and conventional steel that are NOT stainless steel. Nitriding stainless steel will lower the corrosion resistance of the stainless steel. This is because the nitrogen will also react with some of the chrominum (Cr) at the surface of stainless steel to form Chrominum-nitride (CrN). The GLOCK Tenifer process produces a matte, non-glare surface with a 69 Rockwell hardness rating and a 99% resistance to salt water corrosion (which meets or exceeds stainless steel specifications). A Tenifer surface is dull gray in color, and is almost as hard as diamond. After the Tenifer has been created, GLOCK colors the slide, and usually the barrel, to an "off-black" color. If this color is worn off by holster wear, or random abrasion, the Tenifer coating is still there, unaffected.

The GLOCK design has been slightly updated several times throughout its production history. In 1991 a modified version of the recoil spring and recoil spring tube was introduced that is now a single integrated recoil spring assembly that does not disassemble.

Also, the magazine was slightly modified by changing the floorplate, and the follower spring was fitted with a resistance insert at its base. A variety of trigger pull strengths are optional. The factory standard trigger is rated at 5.5 pounds, but by using a different connector it can be increased to about 8 pounds.

The GLOCK frame’s grip was updated with checkering on the front strap and serrations to the rear (these pistols are sometimes called the generation 2 models). In the late 1990s the pistol’s frame was equipped with a light rail, thumb rests, and finger grooves on the front of the pistol grip (generation 3 upgrade). The extractor has also been changed twice and the locking block was enlarged along with the addition of another pin.

GLOCK pistols come in three main sizes, all modeled after the original full-size GLOCK 17. "Standard" full-size models are designed as duty weapons with a large magazine capacity. "Compact" models (for example, the GLOCK 19) are slightly smaller with slightly reduced magazine capacity. "Subcompact" models are even lighter and shorter, and are intended to be used with two fingers on the grip below the trigger guard (for example, the GLOCK 26). Some GLOCK pistols are "C" models ("compensated"), and have slots cut in the barrel and slide, so the exhaust can theoretically reduce muzzle climb.

POCKET CARRY

It is possible to carry a GLOCK subcompact model 26 (9mm) or model 27 (40SW) in your front pocket, if your pants pockets are sufficiently roomy. The next photo shows a GLOCK 27 with a Kel-Tec PF9 and a Kel-Tec P32. The P32 is extremely light and small, and is the best front pocket pistol bar none. The PF9 is the lightest and flattest 9mm pistol made by any gun manufacturer. But you will notice from the photo that the GLOCK 27 is actually shorter in the grip than the PF9, and only a little longer in the slide. In other words, the G27 is a real possibility for front pocket carry in the proper trousers.

For full information on all GLOCK models, you should buy a copy of the annual "GLOCK Autopistols" magazine, which is published every year, and available at many bookstores and magazine stands. The 2009 issue sells for $4.95 (US Dollars). You can also visit this Team GLOCK web page, which has information about every model GLOCK.

Gaston GLOCK, while building up his very successful business, has led an exciting life. Fortune Magazine published an eye-opening article about an attempt to de-fraud Mr. GLOCK, and even to murder him, by his business associates, in 1999. CLICK HERE TO READ THE ARTICLE. See also THIS LINK for the end of the story.

Some information about the business side of the GLOCK company (from Price-Waterhouse-Coopers)...

External link to the PWC article...

Mr Gaston GLOCK, along with his family, is the proprietor of the firm GLOCK Ges. m.b.H. in Austria. He holds direct control of 50% of the group's subsidiaries and of the other 50% via Unipatent Holding SA, of Luxembourg, this being for reasons of fiscal abstraction/fraud. Both entities hold 50% each of GLOCK Inc. Smyrna (VA). This latter company was created in 1986.

Unipatent Holding SA was used by Mr Gaston GLOCK for forwarding very considerable sums each year, officially to pay royalties and other expenses. It should be noted that production costs in Austria amount to US$ 115-130 and that the inter-company selling price is around US$ 200 ( The end-user price around 450-500 USD). Since the margin of US$ 70-85 per unit produced is enormous, the profit is taxable in its entirety.

In fact, and according to the contract, 14% of the volume produced went into Unipatent Holding and must have been transferred into Mr Gaston GLOCK's private accounts. Thus Mr Gaston GLOCK has seen his fortune go from nothing to about US$ 100,000,000 in 1998 in the accounts of the Ferrier & Lullin Bank of Luxembourg.

The simple aim of this operation was to abstract from the Austrian fiscal authorities a significant portion of the profits made by GLOCK Ges. m.b.H. It can be estimated that in fifteen years a sum approaching US$ 50,000,000 has been fiscally laundered and thus that the State of Austria has been injured. It cannot be ruled out that the US Dept. of Treasury also considers itself to be injured by these manipulations.

The fact of artificially increasing the import price of products in the USA can be considered by the American authorities as a straight deception. Moreover, Mr Gaston GLOCK and Mr Charles Ewert have created a whole structure of Off-Shore companies in other countries in order to abstract other sums from the local tax departments and especially to protect G.GLOCK assets against potential US litigations.

Mr Gaston GLOCK has bonds of friendship with the party on a political level and personally with the leader of the FPOe (Mr J. Haider) in Austria and is commonly recognised to be a main sponsor of that political right extremist party. Further, Gaston GLOCK, is considered by journalists as a supporter of an historical well known right extremist "german" ideology.

Mr Charles Ewert (Luxembourg). In 1986, a contract was signed between Mr Gaston GLOCK and himself for management of the funds and administration of Unipatent Holding SA and the companies that the latter controlled and still controls today. When the agreement was finalised a share certificate for LFr 1,250,000 was handed over to Mr. GLOCK. Mr Charles Ewert has since 1990 created a considerable structure of offshore companies consisting of more than 70 units. At the same time, whilst acquiring numerous goods and assets abroad, he keeps a very low profile in Luxembourg so as not to be liable for taxes.

The end of July 1999: Mr Gaston GLOCK was visiting Luxembourg to discuss various problems centring on suspicions that the funds were being embezzled by Mr Charles Ewert. He was subjected to an attempt on his life in the presence of Mr Charles Ewert who fled, leaving Mr Gaston GLOCK alone to combat his assailant for more than ten minutes.

The author of this attempt is a french relation of Mr Charles Ewert and the attempt took place on the latter's own premises, namely the garage at the address of Mr Charles Ewert at Luxembourg. Luxembourg's Justice Dept. charged Mr Charles Ewert with instigation and complicity in murder. Mr Charles Ewert was temporarily set free after two days of imprisonment for lack of sufficient evidence.

It afterwards turned out that Mr Charles Ewert, without either informing Mr Gaston GLOCK nor with his apparent consent, had increased the capital of Unipatent Holding SA to LFr 25,000,000. Mr Charles Ewert was thus able to progressively take control of the GLOCK group and decide its future. Mr Charles Ewert saw himself confronted from the moment that Mr Gaston GLOCK wanted to meet him on account of suspicions of embezzling funds to the situation where Mr Gaston GLOCK was going to ask for detailed explanations regarding the accounts of Unipatent Holding SA and the probable misappropriation of funds for personal use or to revoke the trustee contract with Mr Charles Ewert, which would have had brought into broad daylight the machinery he had put into place to take control of the GLOCK group.

November 1999: Mr Charles Ewert was apparently charged following a criminal complaint brought by the UBS at Luxembourg against two collaborators for embezzlement. According to Mr Gaston GLOCK and his advocates a sum of approximately 30,000,000 US$ had thus been misappropriated by Mr Charles Ewert in the course of the years.

The actors strategies

Mr. Charles Ewert: For at least 10 years Mr Charles Ewert had to at all costs hide from any third parties, and Mr Gaston GLOCK in particular, the increases in the capital of Unipatent Holding.

As Mr Gaston GLOCK saw his personal fortune invested partly in Luxembourg grow over the course of the years he was not unduly worried. Mr Charles Ewert had to keep a low profile towards the Luxembourg authorities and Mr Gaston GLOCK, but outside of Luxembourg he acted as if he was the sole proprietor of 50% of the GLOCK group and acquired assets via one of the numerous companies he had set up over the years.

The founding of various companies was, from Mr Charles Ewert's point of view, judicious in respect of taking control of the GLOCK group when the time came and/or when it was ultimately floated on the stock exchange, upon which he could gain several million US$ at a stroke.

During this period Mr Gaston GLOCK saw himself as the legitimate proprietor of Unipatent Holding, Mr Charles Ewert being no more to him than a proxy/man of straw. Therefore it is not surprising that Mr Gaston GLOCK had relative trust in Mr Charles Ewert for numerous years until the start of 1999 and wanted to hide his relationship with Unipatent Holding from ALL third parties, including the Austrian and American tax authorities. This even went so far as for him to prefer to wrongfully accuse third parties in order to protect the fraudulent system he had set up.

This trust was such that Mr Gaston GLOCK neither checked nor had the accounts of Unipatent Holding evaluated for more than ten years, which is manifestly an act of reprehensible and criminal negligence, all the more so when regular auditing would have immediately put a stop to the misappropriation of the US$ 30,000,000 mentioned above.

We also note that the whole of the Ewert group is directed by two or three persons and that inspection (auditing) is performed by the same staff, which is a feature of Luxembourg that is incompatible with the principle of transparency and equity and leaves the door open to all kinds of abuses. Moreover, Mr Charles Ewert is implicated in various cases of misappropriation of funds, one of which, at Frankfurt, involves DM 40,000,000 and concerns a group of companies called Megatrend. He is also implicated in several cases of fraud and deception, for which a significant number of charges have been laid. At the Luxembourg Parquet Mr Charles Ewert is considered a swindler, a fraud and a dangerous person linked with unsavoury circles (mafia).

The two-millionth GLOCK pistol to be produced by the GLOCK factory was displayed at the 1999 Shot Show. The pistol was engraved "My two millionth pistol" and was signed by the President, Mr. Gaston GLOCK. This huge sales success is a testament to the popularity and desirability of the GLOCK Safe Action Pistol design. Since a large part of this success was due to the overwhelming acceptance by the law enforcement market, this rare collectable was auctioned at the annual conference of the International Association of Chiefs of Police in Charlotte, North Carolina. GLOCK matched the selling price and the proceeds were donated to Concerns of Police Survivors (COPS). COPS is an organization which provides support to the families of law enforcement officers killed in the line of duty.

The GLOCK philosophy embodies close cooperation with law enforcement and military organizations, as well as strict compliance with all applicable laws, rules and regulations. GLOCK continues its leadership with firearms innovation and design and supports the rights of citizens of all countries to practice the responsible and lawful use of firearms.

In 2005, Gaston GLOCK was ranked number 43 on a list of the 100 wealthiest Austrains in the Austrian economy magazine Trend.

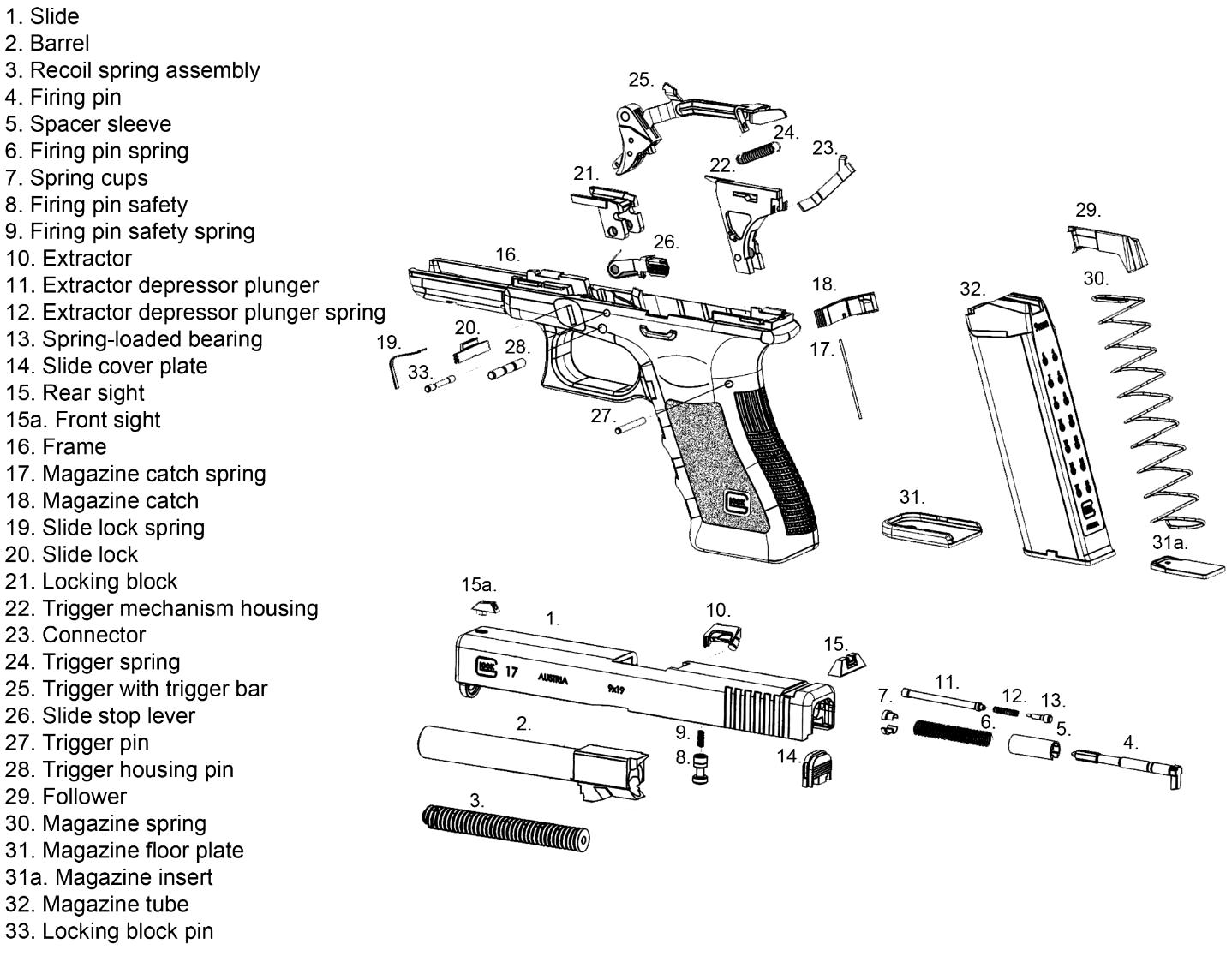

How many parts does a GLOCK have?

According to the current manual the GLOCK has about 34 parts. They are:

- # Part

- 1 Slide

- 2 Barrel

- 3 Recoil spring assembly

- 4 inapplicable, incorporated in part 3

- 5 Firing pin

- 6 Spacer sleeve

- 7 Firing pin spring

- 8 Spring cups

- 9 Firing pin safety

- 10 Firing pin safety spring

- 11 Extractor

- 12 Extractor depressor plunger

- 13 Extractor depressor plunger spring

- 14 Spring-loaded bearing

- 15 Slide cover plate

- 16 Rear sight

- 16a Front sight

- 17 Receiver

- 18 Magazine catch spring

- 19 Magazine catch

- 20 Slide lock spring

- 21 Slide lock

- 22 Locking block

- 23 Trigger mechanism housing with ejector

- 24 Connector

- 25 Trigger spring

- 26 Trigger with trigger bar

- 27 Slide stop lever

- 28 Trigger pin

- 29 Trigger housing pin

- 30 Follower

- 31 Magazine spring

- 32 Magazine floor plate

- 32a Magazine insert

- 33 Magazine tube

- 34 Locking block pin (some models)

- 35 Channel Liner

The actual total number is open to a great deal of interpretation:

- - #3: the 'Recoil spring assembly' is made of several parts

- - #8: the 'Spring cups' are 2 parts

- - #16 & 16a: the 'Front and Rear sight' are 2 parts

- - #23: the 'Trigger mechanism housing with ejector' is made of several parts

- - #26: the 'Trigger with trigger bar' is made of several parts

- - #34 the 'Locking block pin' is not found on some models

- - #32 & 32a: the 'Magazine floor plate and Magazine insert' are 2 parts

- - Adjustable sights have a lot of individual parts

- Back To Top

HERE IS A DIAGRAM OF ALL THE GLOCK PARTS

Here is information for those who would like to write or otherwise get in touch with GLOCK, Inc.

Scanned from 2009 GLOCK Autopistols

The Newest GLOCKS -- the RTF2; and Short-Framed 10mm G20 and G29

In 2009 GLOCK introduced a new model," the G22 RTF2 with new slide serration pattern and rough textured grip. The G22 RTF2 (Rough Textured Frame version #2) pistol design has more than 4,000 raised pyramids on the front, rear and sides of the polymer receiver. The raised pyramids are also located on the thumb rests for increased grip traction. In addition, the slide on the G22 RTF2 has a new, modern look with crescent shaped serrations located at the rear of the slide.

GLOCK also announced the introduction of a "short framed" G20 and G29 in 10mm caliber. A six inch hunting barrel will be available for the larger firearm.

Find full Gen4 information and photos on the Firearm Blog.

Are GLOCK handguns safe?

Some people believe that GLOCKS are unsafe handguns. They give the following reasons:

- 1. There is no manual safety.

- 2. The "out of the box" GLOCK trigger is relatively light and short, compared for example to the S&W Sigma, or the Kel-Tec P-11.

- 3. There is no "loaded chamber indicator." (NOTE: All currently manufactured Glocks have a loaded chamber indicator. The old model extractor has been reshaped and protrudes from the slide when a round is chambered.)

- 4. There is no magazine dis-connect.

In February 2002 there was an incident in Philadelphia in which a police officer took her handgun into her son's school during career day. A child asked to see her handgun, so she removed the magazine and handed the gun to the child. The child pulled the trigger and the gun fired! The police officer had fogotten to remove the round from the chamber! Fortunately, no one was hurt. And yes, her handgun was a GLOCK.

Some handguns by other makers DO have magazine dis-connects. If you drop the magazine, the gun will not fire. But as someone once quipped: "Glocks are very good at what they were made for - shooting fast."

Several years ago in Midland, Texas a police officer accidentally discharged his handgun when he accidentally dropped the loaded gun, reached for it with both hands to try to catch it, and grabbing it with one hand he pulled the trigger discharging the bullet into his other hand. It was a GLOCK.

Those who prefer GLOCKS will say: Every accident is preventable. There are no "accidental discharges." There are only "negligent discharges." It IS true: We all have a responsibility to use caution when handling a handgun, people who choose to carry a GLOCK must be unwaveringly cautious.

The GLOCK is a superb fighting handgun. It does exactly what it was designed to do, and it was designed to be able to go into action without fumbling with safety levers, or checking this thing or that thing. It was not designed to be a "go to the range and have fun" gun. It was designed as a military weapon. Pick it up, point it, pull the trigger, and it will go "bang."

Those who carry GLOCK sidearms must always remember the second rule of firearms: NEVER PUT YOUR FINGER ON THE TRIGGER UNTIL YOU ARE READY TO SHOOT. If you will constantly remember that one simple rule, you will find your GLOCK to be a safe weapon. Subsidiary rules are: 1) Never put your finger to the trigger, even if you have removed the magazine, until you have visually checked to see if the chamber is empty. Check it twice! and 2) Never allow anything to get in your holster (or in your pocket if you are carrying in your pocket) except for your GLOCK. A coin, a pencil, a piece of paper, WHATEVER. NOTHING should be in a position where it could touch the trigger of your GLOCK. 3) If you accidentally drop your GLOCK, don't try to catch it! Let it go! Let it hit the floor! It will NOT fire on impact. But if you try to catch it, your finger may hit the trigger, and you may press the trigger hard enough to fire.

More than any other firearm, your GLOCK should be carried in a holster that covers the trigger.

People who carry a GLOCK stuck in their wasteband, or in a pocket, without a holster, are ASKING FOR TROUBLE! When re-holstering your GLOCK, pay CLOSE ATTENTION to what your are doing. Don't let a holster flap, or a shirt-tail get into the trigger guard, where it might press on the trigger. You may have a NEGLIGENT discharge if you aren't paying attention.

Note: if you are afraid of the light trigger pull on your GLOCK, the company (or a GLOCK armorer at your local gun shop) can adjust your GLOCK to have a heavier trigger pull. This has come to be called a "New York Trigger." There are also companies who can install a manual safety lock on your GLOCK.

The GLOCK is a superb and superior firearm for those who will treat it with respect, and maintain gun safety rules at all times. But GLOCKS are NOT for people who are inclined to be lax about gun safety rules. Of course

there are NO guns at all that are appropriate for careless people,

but that goes double for GLOCKS.

Elroy Gonzalez was NEGLIGENTLY shot in the head and seriously injured in 1996 while being arrested by a Kentucky police officer. Ronnie Earl Kimbrell was shot in the back by a South Carolina state trooper in 1995 while being arrested for an alleged traffic violation. The trooper said he was trying to handcuff Kimbrell when he accidentally fired his gun. James Lancaster was killed Aug. 8, 1996, after a sheriff’s deputy unintentionally shot him. At the time he was shot, Lancaster was being forced to the ground after a 20-mile car chase. The officer said he didn’t intend to fire the weapon. It was a NEGLIGENT discharge.

Whatever gun you carry, GLOCK or 1911, or whatever,

NEVER PUT YOUR FINGER ON THE TRIGGER UNLESS YOU MEAN TO SHOOT YOUR FIREARM!

If you are holding your firearm in one hand, and trying to do something which requires two-handed dexterity, you are endangering yourself and others.

Links with valuable GLOCK information...

GLOCK Generation 4 Information and Photos

The GLOCK FAQ

General GLOCK Information (from the GLOCK FAQ)

The Official GLOCK Website

GLOCK Training (for Armorers, etc)

Team GLOCK

GLOCK Sport Shooting Foundation

The Unofficial GLOCK Users Manual (PDF Format)

GLOCK Wikipedia Article

GLOCK Factory Trigger Options

Is the GLOCK Inherently Unsafe? Phil Elmore Article

Plastic Perfection, Kokalis

The Best GLOCK Yet, Wiley Clapp

GLOCKTalk is the Big GLOCK Forum

GLOCK-Guns.Com has lots of Reviews and Information

Lonewolf, the World's Largest Distributer of GLOCK parts and accessories

TopGLOCK for Parts and Accessories

Glockmeister

Brownells Parts

Bar-Sto Barrels

Storm Lake Barrels

Glockifieds.Com (GLOCK classified ads)

Christian Gun Owner's Comments on GLOCKS

The Gun Zone GLOCK Pages (A Somber Appraisal)

GLOCK Kabooms!

Gun Zone GLOCK Kaboom! FAQ

HighPowers&Handguns Reviews the GLOCK 17

The Meaning of GLOCK Serial Numbers (GLOCKFAQ)

The GLOCK Serial Number Research Project on GLOCKTALK

The Famous GLOCK 21 "Torture Test"

Video: How to Detail Strip A GLOCK

How to Detail Strip A GLOCK (Not a Video)

Gunblast.com Reviews the GLOCK 37 and the GAP .45 cartridge

The Development of GLOCK'S very own cartridge the "GAP." (GLOCK AUTO PISTOL .45 Caliber)

Wikipedia Article on the GAP .45 Cartridge

September 2009 Business Week Article

There are also several good books about GLOCK pistols that you might like to buy at Amazon.com:

The Gun Digest Book of the GLOCK, by Patrick Sweeney

Living with GLOCKS, by Robert H. Boatman